Analysis of recycled electrolyte materials from all-solid-state battery

Research project of Reem Ismail, student of the Soft Nanoscience program of GS@UGA, at the LEPMI, Grenoble.

Within the next decade, new generations of lithium batteries based on silicon/carbon and Li metal anodes are expected to take over the battery market. Among those, all-solid-state batteries (ASSBs) comprising a Li metal anode and a solid-state electrolyte are a target of choice as their properties should overcome all previous battery technologies. Indeed, only ASSBs Li batteries are expected to fulfill the needed cell gravimetric energy density, cyclability, sustainability, and recycling specifications demanded by electromobility and stationary applications.

In this context, the EU-funded Horizon Europe SEATBELT project aims to drive the development of a cost-effective, durable all-solid-state lithium battery utilizing sustainable materials by 2026. The SEATBELT cell prioritizes safety through design, utilizing sustainable and recyclable materials, with the goal of achieving high energy densities (>380 Wh/kg) and extended cyclability (>500 cycles) by 2026, aligning with the 2030 European targets. SEATBELT aims to reach its first technological milestone by developing an all-solid-state battery cell tailored to meet the demands of Electric Vehicles (EVs) and stationary industries.

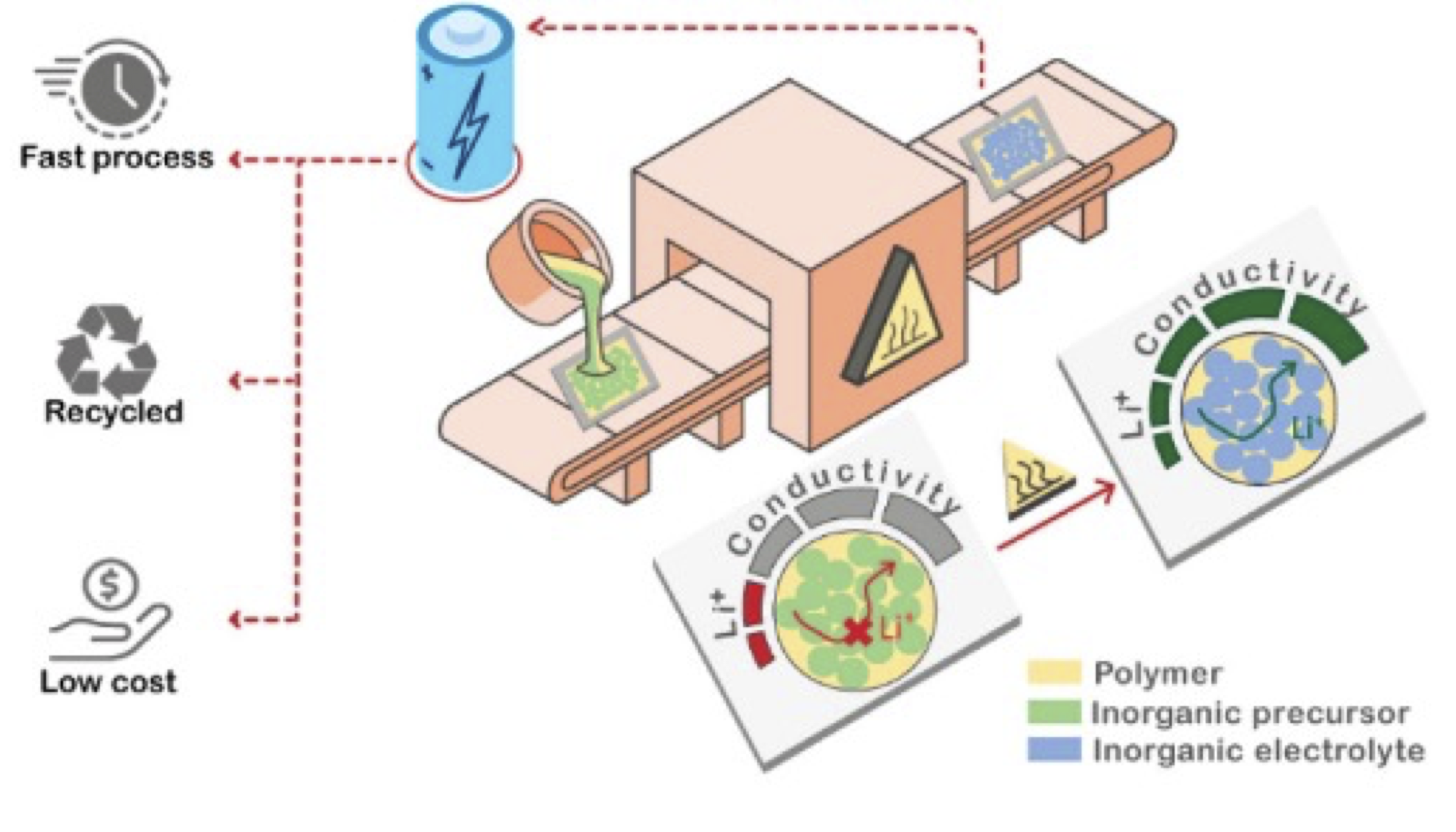

This master internship position is dedicated to advancing research in the synthesis and recycling of ASSBs. At the heart of SEATBELT's ASSBs lies halide-based electrolytes, such as Li3InCl6. These electrolytes, unlike their oxide or sulfide counterparts, offer larger ionic radii, fostering superior ion mobility and excellent deformability. Li3InCl6, in particular, has garnered significant interest due to its composition of non-critical raw materials, high ionic conductivity (reported up to 2 mS/cm at room temperature), and its environmentally friendly and cost-effective water-based synthesis method. This synthesis approach holds promise for the eco-friendly recycling of halide-based ASSBs, as illustrated in Figure 1, highlighting a sustainable path forward for battery technology.

The SEATBELT consortium comprises 15 partners throughout 8 European countries. Within this consortium, the internship master student will join the LEPMI laboratory on Grenoble / Saint Martin d’Hères Campus which specialized in electrochemistry and physical-chemistry of materials and interfaces. Consequently, the master student will focus on the electrolyte by aiming at optimizing their recycling process to formulate new batches of electrolytes. Then, the recycled materials will be characterized by electrochemical methodologies and physico-chemical analysis..

Requirement

This project is dedicated to M1 students of the Soft Nano Program with background in material sciences, chemistry, or other related topics with strong interest in energy storage devices.

References

[1] X. Li, et. al, Energy Environ. Sci., 2019,12, 2665-2671 Air-stable Li3InCl6 electrolyte with high voltage compatibility for all-solid-state batteries https://doi.org/10.1039/C9EE02311A

[2]7N. Stankiewicz, et.al, ACS Appl. Polym. Mater. 2024 In Situ Hybrid Solid-State Electrolytes for Lithium Battery Applications https://doi.org/10.1021/acsapm.4c00473

Published on June 3, 2024

Updated on September 4, 2024